What Are Custom Patches and Why Is Their Backing Important?

Custom patches have become essential elements in personalising clothing, accessories, and promotional items across industries. From military uniforms and corporate apparel to fashion statements and collectible merchandise, these embroidered or woven designs serve both functional and aesthetic purposes.

The backing of a patch refers to the material layer attached to its reverse side. This component determines three critical factors:

- Application method – whether you’ll sew, iron, stick, or magnetically attach the patch

- Durability – how long the patch remains securely fastened through wear and washing

- Versatility – whether the patch can be removed, repositioned, or swapped between garments

Selecting appropriate backing for custom iron on patches directly impacts how well your patches perform in their intended environment. A military uniform requiring frequent patch changes demands different backing than a promotional jacket patch meant to last years. The fabric receiving custom iron on patches also plays a crucial role—cotton responds differently to heat-activated adhesives than leather or nylon.

Understanding backing options transforms patch selection from guesswork into informed decision-making. The right backing ensures your patches stay attached when needed, look professional throughout their lifespan, and apply easily to your chosen surface without damaging the underlying material.

What Are the Different Types of Backing Available for Custom Patches?

There are seven main types of patch backing that serve different purposes in the world of custom patches. Each backing option has its own unique qualities that determine how patches attach to clothing, how long they last, and how they can be used practically.

1. Plastic Backing

Plastic backing consists of a thin, matte plastic layer that provides structural support to embroidered, woven, or dye-sublimated patches. This backing type maintains the patch’s shape and prevents distortion during the sewing process. The rigid foundation proves particularly valuable for intricate designs that require dimensional stability. Manufacturers commonly pair plastic backing with traditional sew-on applications, creating patches that retain their professional appearance even after repeated handling and washing.

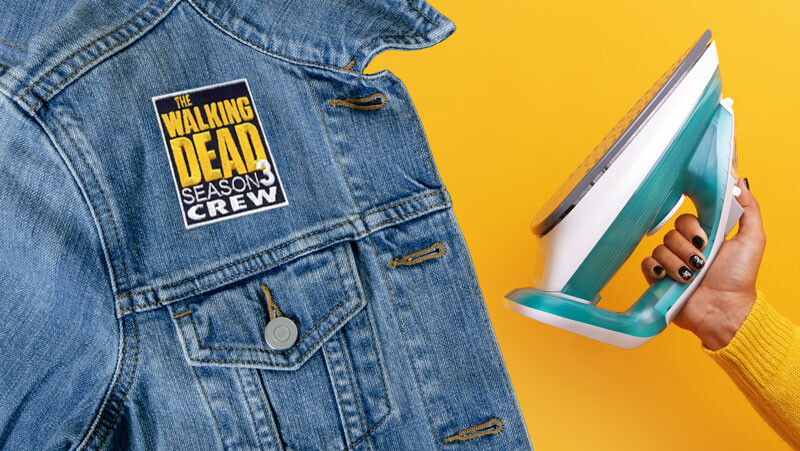

2. Iron-On Backing

Heat-activated adhesive defines iron-on backing, allowing patch attachment through simple household iron application. The thermoplastic adhesive melts when exposed to heat, bonding the patch directly to fabric fibres. This backing type eliminates the need for sewing skills or specialised equipment, making it the most accessible option for home crafters and casual users. Iron-on patches typically endure 25-30 wash cycles before adhesive strength diminishes, though sewing around the edges extends their lifespan considerably.

3. Velcro Backing

The hook-and-loop system of velcro backing revolutionised patch versatility in professional settings. The hook component (rough, scratchy side) attaches permanently to the patch, whilst the loop component (soft, fuzzy side) secures to the garment. This two-part system enables instant removal and repositioning without damaging either the patch or fabric. Military personnel, law enforcement officers, and tactical professionals favour this backing for its flexibility in displaying rank insignia, unit identifications, and morale patches that change based on assignment or preference.

4. Self-Stick Backing

Adhesive-coated self-stick backing functions identically to standard stickers, featuring a peel-away protective layer that reveals sticky backing. This temporary solution suits single-event applications, promotional giveaways, and situations requiring quick attachment without permanent commitment. The adhesive weakens progressively with exposure to moisture, heat, and repeated handling, making it unsuitable for garments requiring regular laundering.

How Does Fabric Type Influence the Choice of Patch Backing?

The fabric you’re attaching a patch to directly determines which backing types will work effectively and which will fail. Each material has unique properties—texture, heat tolerance, weave density, and flexibility—that interact differently with adhesives, heat, and stitching methods.

Cotton Patches and Fabric Compatibility

Cotton stands as the most versatile fabric for patch backing compatibility. The natural fibres create an ideal surface for heat-activated adhesives, making iron-on backing particularly effective on cotton patches and cotton garments. The fabric’s ability to withstand high temperatures without melting allows the adhesive to bond properly during application. Sew-on options with plastic backing also perform exceptionally well on cotton, as the needle passes through the material cleanly without causing runs or tears. Even temporary adhesive backings grip cotton’s textured surface more reliably than smoother synthetics.

Synthetic Fabrics Require Specific Backing Solutions

Nylon patches and polyester fabrics present distinct challenges that rule out certain backing types entirely. Iron-on backing fails on these materials because the heat required to activate the adhesive often melts or warps the synthetic fibres, creating permanent damage. The smooth, tightly-woven surface of nylon also prevents adhesives from gripping effectively, causing patches to peel away after minimal wear.

Sew-on backing with plastic support becomes the primary choice for synthetics, providing secure attachment without heat exposure. Velcro backing offers another excellent solution, particularly for nylon patches used in tactical or outdoor applications where the fabric’s water resistance and durability matter most. The hook-and-loop system mechanically fastens to the fabric without relying on adhesion or heat bonding.

Leather and Vinyl Demand Robust Attachment Methods

Leather patches and vinyl materials require the strongest attachment methods available. These dense, non-porous surfaces reject adhesives almost entirely, making iron-on and self-stick backings completely unsuitable. The material’s thickness and resistance to penetration mean that sewing requires specialised needles and considerable force.

Sew-on backing remains the gold standard for leather applications, though the process demands heavy-duty thread and careful technique to avoid tearing. Vel

Which Backing Types Offer the Best Durability for Long-Term Use?

Sew-on patches with plastic backing deliver the highest durability for long-term applications. The combination of stitched attachment and rigid plastic support creates a bond that withstands years of wear, frequent washing, and harsh conditions without degradation.

Ranking Durable Patch Backings by Longevity

When selecting long-lasting patches, understanding the lifespan of each backing type helps match your needs with the right option:

1. Sew-on with Plastic Support (Most Durable)

- Remains secure indefinitely when properly stitched

- Plastic layer prevents fraying and maintains shape integrity

- Survives industrial washing cycles and heavy-duty use

- Ideal for uniforms, workwear, and heirloom items

2. Iron-On Backing (Moderate Durability)

- Maintains adhesion for approximately 25-30 wash cycles

- Heat and detergent gradually weaken the adhesive bond

- Performance varies based on water temperature and washing frequency

- Adding perimeter stitching extends lifespan significantly

3. Velcro Backing (Variable Durability)

- Longevity depends entirely on stitching quality and hook-loop integrity

- Professional stitching provides years of reliable attachment

- Hook material may accumulate lint, reducing grip strength

- Loop side typically outlasts hook side in durability

4. Pin Backing (Reusable but Limited)

- Metal components resist corrosion and maintain function

- Butterfly clutches may loosen with repeated use

- Creates small holes in fabric over time

- Best suited for occasional wear rather than daily use

5. Adhesive Backings (Shortest Lifespan)

- Self-stick patches weaken after 5-10 washes

- Moisture and heat accelerate adhesive breakdown

- Magnetic backings maintain hold but limited to lightweight patches

- Designed for temporary or single-event applications

Factors Affecting Patch Backing Durability

The washing method dramatically impacts how long durable patch backings maintain their integrity. Hand washing extends the life of iron-on and adhesive options, whilst machine washing on gentle cycles with cold water preserves.

What Are the Advantages and Limitations of Iron-On Backing?

Iron-on patches offer unmatched convenience for home application, requiring only a household iron and a few minutes to permanently attach patches to fabric. The heat-activated adhesive bonds quickly to compatible materials, making them ideal for DIY enthusiasts, parents adding patches to children’s clothing, or anyone seeking a no-sew solution.

Key Advantages of Iron-On Patches

Simple application process stands as the primary benefit. Position the patch, apply heat with an iron for 30-45 seconds, and the adhesive creates a strong bond without threading needles or visiting a tailor. This accessibility makes iron-on backing particularly attractive for:

- Quick repairs and customisation projects at home

- Adding patches to children’s uniforms or school bags

- Temporary branding on event merchandise

- Crafting projects requiring multiple patch applications

Cost-effectiveness represents another significant advantage. Iron-on patches eliminate professional application fees, allowing bulk customisation without additional labour costs. Many users successfully apply dozens of patches in a single session, perfect for team uniforms or promotional giveaways.

The backing also provides moderate durability for everyday wear. When properly applied to suitable fabrics, iron-on patches withstand 25-30 wash cycles before showing signs of lifting or adhesive degradation. Reinforcing the edges with basic stitching extends this lifespan considerably.

Critical Limitations to Consider

Fabric compatibility severely restricts iron-on patch applications. The heat-activated adhesive fails to bond effectively with:

- Nylon and other synthetic materials that melt under high heat

- Leather and vinyl surfaces that cannot absorb the adhesive

- Corduroy fabrics where ridges prevent uniform contact

- Waterproof or treated materials with protective coatings

Attempting to iron patches onto incompatible fabrics results in poor adhesion, potential fabric damage, or melted synthetic fibres. Cotton, cotton blends, and denim remain the safest choices for iron-on backing.

Temperature sensitivity poses ongoing challenges. Excessive heat during application can scorch delicate fabrics or melt the patch itself, whilst insufficient heat prevents proper bonding. Different fabric weights require adjusted iron temperatures, creating a learning curve for

When Is Velcro Backing the Most Practical Choice?

Velcro backing becomes the most practical choice when you need the flexibility to remove, swap, or reposition patches frequently. The hook and loop system consists of two components: the rough hook side sewn directly onto your patch, and the soft loop side attached to your garment, creating a secure yet easily detachable bond.

The velcro patch benefits shine in professional environments where personnel must adapt their identification quickly. Military uniforms exemplify this perfectly—service members can swap unit patches, rank insignia, or flag patches within seconds when transferring between assignments or updating their credentials. Law enforcement officers similarly benefit from this system, allowing them to modify patches for different duties, specialised units, or ceremonial occasions without maintaining multiple uniforms.

The hook and loop system offers distinct advantages beyond simple removal:

- Instant customisation without tools or heat application

- Preservation of garment integrity since you’re not repeatedly sewing and removing patches

- Cost-effective rotation of seasonal or promotional patches on the same base garment

- Reduced wear on expensive uniforms from constant needle punctures

Tactical gear users particularly value velcro backing because it accommodates the dynamic nature of their work. A single jacket can display different team identifiers, morale patches, or operational insignia depending on the mission requirements. Emergency services personnel also adopt this backing type, enabling quick identification changes between departments or roles.

Velcro backing comes in two configurations: single-sided (hook only) or double-sided (fuzzy material on both sides). Single-sided velcro requires you to sew or attach loop material to your garment first, whilst double-sided options provide more versatility by adhering to any compatible velcro surface.

The durability of velcro-backed patches depends heavily on the stitching quality securing the hook material to the patch. Well-constructed velcro patches withstand hundreds of attachment cycles and regular washing when properly maintained. The adhesive strength remains consistent across temperature variations, making velcro suitable for outdoor gear, sports uniforms, and workwear exposed to challenging conditions.

How Suitable Are Self-Stick and Pin Backings for Temporary Applications?

Self-stick and pin backings excel when you need a patch for short-term use without permanent attachment. These temporary patch backings offer the flexibility to apply and remove patches without damaging the underlying fabric, making them ideal for situations where commitment isn’t required.

Self-Stick Backing

Self-stick backing functions like a sticker, featuring an adhesive layer protected by a peel-away film. This backing type works perfectly for:

- Single-day events such as conferences, trade shows, or festivals

- Promotional campaigns with limited duration

- Testing patch placement before committing to permanent attachment

- Rental uniforms or borrowed garments

- Children’s costumes that change frequently

The adhesive strength varies by manufacturer, but most self-stick patches maintain their grip for several hours to a few days. Heat, moisture, and repeated handling gradually weaken the bond. Washing typically destroys the adhesive completely, rendering the patch unusable for reattachment. Some users apply self-stick patches to smooth, non-fabric surfaces like laptop cases or folders, where they perform better than on textured materials.

Pin Backing

Pin backing transforms patches into wearable accessories similar to brooches or badges. A metal pin protrudes from the back of the patch, secured by a butterfly clutch or similar fastener. This backing type suits:

- Jackets and bags where pin holes won’t cause concern

- Rotating patch displays on the same garment

- Collectible patches that move between different items

- Professional settings requiring daily uniform changes

- Delicate fabrics that shouldn’t endure heat or adhesives

Pin backings offer unlimited reusability—the same patch can transfer between dozens of garments without losing functionality. The main limitation involves the small holes left in fabric after removal, though these typically close on their own in most materials. Heavier patches may sag or tilt on lightweight fabrics, and the pins can catch on other items during storage or wear.

Common Advantage

Both backing types share a common advantage: they require no special tools, skills, or preparation. Anyone can apply a self-stick patch in seconds or attach a pin-backed patch with minimal effort. This accessibility makes them popular choices for last-minute needs or situations where sewing equipment isn’t available.

What Unique Applications Do Button Loop and Magnetic Backings Serve?

Button Loop Patches: A Time-Honoured Solution

Button loop patches scouting badges represent a traditional attachment method where a twisted fabric loop extends from the patch’s back, designed to hook around a button. This backing style earned its reputation through decades of use in scouting organisations, where merit badges hang from uniform shirts using existing buttons. The system allows young scouts to display their achievements without requiring sewing skills or parental assistance.

The button loop method works best when garments already feature strategically placed buttons. Scout uniforms typically include dedicated button placements for this purpose. Youth organisations favour this approach because children can independently add or rearrange their patches, fostering a sense of accomplishment and ownership over their uniform displays.

Magnetic Backings: A Versatile Alternative

Magnetic backings deliver a completely different solution, eliminating the need for any sewing, heating, or piercing of fabric. These patches contain a small, powerful magnet sandwiched between the patch face and backing material. An oppositely charged magnet disc sits on the garment’s reverse side, creating a secure hold through the fabric layers.

The magnetic patch advantages novelty use become apparent in several specific scenarios:

- Delicate fabrics: Silk, chiffon, or vintage textiles that shouldn’t be punctured or exposed to heat

- Rental garments: Costumes or formal wear where permanent alterations aren’t permitted

- Frequent rotation: Collections displayed on jackets or bags where users want daily variety

- Children’s clothing: Quick attachment without sharp pins that pose safety risks

- Promotional events: Staff or attendee identification that needs rapid distribution and collection

Magnetic backings shine in novelty applications where the patch serves as a conversation piece rather than a permanent garment feature. Trade show vendors distribute magnetic patches knowing recipients can immediately attach them to clothing without tools. Businesses use them for temporary employee identification during special events.

The strength of magnetic backings varies based on patch size and magnet quality. Smaller patches (under 5cm) hold securely on most fabric weights. Larger patches may require multiple magnet points or stronger rare-earth magnets. Thick fabrics like heavy denim or winter coats can reduce magnetic grip, making this backing less reliable for outdoor work uniforms.

Button loop patches maintain their niche in traditional youth organisations and ceremonial settings where preserving garment integrity is paramount.

How to Choose Between Permanent and Removable Patch Backings

Deciding between permanent and removable patch backings depends on a few factors:

- How often you’ll need to reposition or swap patches

- The intended lifespan of the garment

- Whether you value flexibility over long-term security

Permanent backings like plastic-backed sew-on options, which can be learned more about in this guide on how to sew a patch, create lasting bonds. On the other hand, removable backings such as Velcro, pins, or magnets allow for frequent changes.

Garment Type and Ownership

Do you own the garment or uniform you’re attaching patches to? Rental uniforms, work clothing provided by employers, or borrowed items require removable solutions to avoid permanent alterations. Velcro or pin backings preserve the original garment’s condition, making them ideal for temporary assignments or seasonal work positions.

Personal clothing offers more freedom. If you’re customising a favourite jacket you plan to keep for years, sew-on backing with plastic support delivers maximum durability. For fashion-forward individuals who rotate patches based on trends or moods, Velcro or magnetic options provide the flexibility to refresh looks without commitment.

Usage Frequency and Laundering Demands

How often will the patched item face washing machines and dryers? Garments requiring frequent laundering—such as work uniforms, children’s clothing, or sports gear—benefit from considerations that prioritise durability. Sew-on backing withstands hundreds of wash cycles, while iron-on backing maintains adhesion through 25-30 washes before potentially requiring reinforcement.

Items worn occasionally or displayed rather than washed suit removable backings. Collector jackets, ceremonial uniforms, or decorative bags rarely see washing machines, making the reduced durability of adhesive, pin, or magnetic backings acceptable trade-offs for convenience.

Collection and Display Purposes

Are you building a patch collection you’ll want to reorganise or showcase differently over time? Collectors often prefer removable backings that allow patches to move between display boards, garments, and storage without damage. Pin backings transform patches into wearable art that transitions from denim jackets to canvas bags to felt boards.

Military personnel, law enforcement officers, and outdoor enthusiasts may also find value in removable backings for their specific needs. Tactical gear often requires adaptability in order to accommodate different missions or environments. By opting for Velcro or magnetised patches on uniforms or backpacks, these individuals can easily swap out insignias based on operational requirements while maintaining a professional appearance.

Conclusion

Selecting the right backing transforms a custom patch from a simple accessory into a functional, long-lasting addition to your garment or item. The Definitive Guide to Choosing the Right Backing for Your Custom Patches emphasises one critical principle: your intended use should always drive your backing choice.

Before committing to a backing type, ask yourself these essential questions:

- Will this patch remain on one garment permanently, or does it need to move between items?

- How frequently will the item be washed or exposed to wear?

- What fabric will host the patch?

- Does the application method need to be simple enough for home use?

- Is professional appearance or casual flexibility more important?

The choosing custom patch backing summary best practices boil down to matching your specific requirements with the appropriate backing characteristics. A military uniform demands the flexibility of Velcro, whilst a treasured jacket deserves the permanence of sewn-on patches with plastic backing. Event merchandise works perfectly with self-stick backing, and children’s clothing benefits from the simplicity of iron-on options.

Test your backing choice on a small fabric sample when possible, particularly for valuable or delicate materials. This simple step prevents disappointment and ensures your patch performs exactly as expected.

Your patch represents your brand, achievement, or personal style. The backing you choose determines whether it stays securely in place through years of use or falls off after the first wash. Take the time to assess your needs, consult this guide when uncertain, and select the backing that aligns with both your practical requirements and long-term expectations. The right backing choice ensures your custom patch looks professional and performs flawlessly for its entire lifespan.

More about How to Turn Your Art into a High-Quality Acrylic Pin in 5 Simple Steps